The goals of automatic deboning equipment have historically remained the same and revolve around high yield, low bone content and speed.

As technology has advanced, there’s a growing demand for equipment that can handle various bird sizes and a variety of incoming product quality efficiently while maintaining high yields.

“Baader responded to these trends by integrating individual bird measurements, advanced software and superior cutting and scraping mechanisms,” said Oliver Hahn, chief executive officer of the Kansas City, Kan.-based company.

For instance, the Baader 661 Front Half Deboner processes front halves without wings attached up to 11.5 lbs average live weight. This machine produces boneless skinless breast fillets and tenders in various configurations based on customer requirements. The company’s 660A Breast Cap Deboner processes breast caps up to 8 lbs average live weight, producing boneless skinless breast fillets and tenders in various configurations, while the Baader 656 Front Half Deboner processes front halves with or without wings attached up to 8 lb average live weight.

“Additionally, the Baader Refiners complements the deboning process by recovering high-quality, valuable meat from byproducts of any deboning process,” Hahn said.

Jeroen Bohm, product director at Meyn Poultry Processing Solutions, based in Oostzaan, Netherlands, noted there are two significant deboning trends in the poultry processing industry.

“One is the need for high-capacity inline deboning of dark meat, with the focus of maximum yield,” he said. “On the breast deboning side, we see the need for increased weight.”

For the latter, Meyn offers the Rapid Breast Deboner, which is a fully automated system that can debone any recipe and has the capacity for 7,000 breasts per hour.

“It’s highly flexible and we can extend the machine with later upgrades, increasing profitability,” Bohm said, explaining it can process wingless front halves and breast caps on a single machine and has over a dozen end-products with touch screen operated recipe control.

One of Meyn’s latest equipment offerings in the area is the Physic In-Line Thigh Deboner M1.0, which boasts a compact two-carousel footprint of 377 square feet, and capable of converting 15,000 whole legs into boneless thigh fillets per hour with zero people needed. By integrating thigh deboning carousels within the cut-up line, the solution can bypass legs based on weight and quality.

“We are now moving to an In-Line Drumstick Deboner,” Bohm said.

Talking turkey

Tom Wisvari, director of processing for Oakwood, Ohio-based Cooper Farms, noted it’s challenging to automate turkey deboning equipment because of variations in the size of birds arriving at the plant.

“The trends that I see are more toward semi-automation, helping to reduce the effort a team member needs to give rather than job elimination,” he said. “I am also seeing trends toward foreign material detection through optics and X-ray. We are not seeing too much in the way of robotics in this area of the plant.”

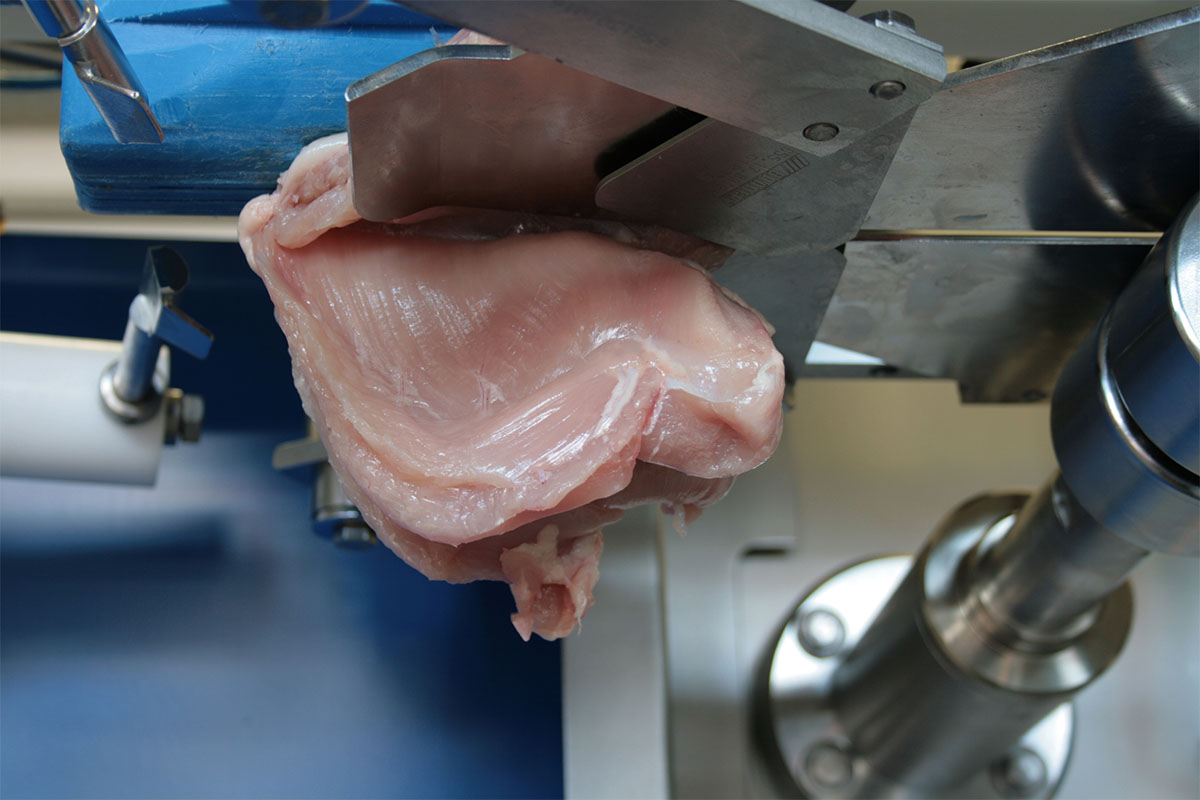

Baader deboners allow users to make adjustments for different cuts and poultry products. (Source: Baader)

Baader deboners allow users to make adjustments for different cuts and poultry products. (Source: Baader)Custom treatment

Customizable equipment that can be tailored to fit the specific needs of different poultry processing operations is important, as it allows for more efficient and faster processing.

For instance, Cooper Farms sees a wide range of flexibility with its deboning equipment, allowing the company to dial in to maximize yields, and accommodate the sales mix for the day.

“I believe that processors should operate in a continuous improvement mentality, so always looking to enhance not only the equipment, but the process too,” Wisvari said.

All Baader deboners allow for flock adjustment during the production process without stopping. This means users can adjust settings for different cuts and products, allowing for flexibility in processing.

“For example, users of the Front Half Deboner 661 can easily switch between butterfly or single breast fillets, tender in or out with a quick changeover and a click of a button on the HMI,” Hahn said. “It can process up to 85 front halves without wings per minute.”

This precision ensures that as much meat as possible is harvested, reducing waste and improving profitability.

“By optimizing cutting processes and utilizing advanced technology, we ensure that our equipment delivers exceptional efficiency and yield, helping processors enhance their bottom line,” Hahn said.

Safety and Efficiency

Baader incorporates robust safety features in its equipment to protect operators and maintain a secure ergonomic working environment for line workers.

“From safeguarding mechanisms to emergency stop protocols, our equipment adheres to strict safety standards to mitigate potential hazards in the processing environment,” Hahn said. “We understand the importance of minimizing downtime and maximizing operational efficiency. Therefore, our machines feature accessible components and user-friendly interfaces, simplifying the cleaning and maintenance process for operators.”

The company also provides comprehensive training support to ensure all customers can operate the deboning equipment effectively. From initial installation to ongoing production support, Baader’s experienced service team assists customers every step of the way, providing operator training, maintenance videos and in-person programs tailored to the specific needs of customers, empowering them to maximize the potential of the equipment.

All equipment at Cooper Farms is guarded in a manner to maximize safety.

“Additionally, there are pull cord E-stops so that any team member at any time can stop the line,” Wisvari said. “We maintain a robust safety program and cross-functional safety team.”

Meyn offers a safety sensor around its breast deboning equipment, and doors around the carousel.

“It’s a critical operation deboning, so you need to have a good view of the process to operate them,” Bohm said. “We have placed a safety fence around it, and the controls are done on the safety fence, and all adjustments can be made from outside.”

The ability to customize deboning equipment is transforming the poultry industry, offering unparalleled flexibility, efficiency and safety to meet evolving market demands.